Flozone Integrated Water, Energy & Air Management Program: Eliminates Chemicals/Pays for Itself

- Flozone is using Iot Technology to Reduce Data Center Cooling Costs, Carbon and Water.

- Proven at hundreds of buildings over 14 years

- Now Being Introduced to Data Centers with New Patent

Pangea’s Vertically Integrated Data Center Solutions Include Deployment of Proven Iot Cooling Technology

- Replaces condenser chemicals with O3 – Mother Nature’s Cleanser kills pathogens

- Reduces water consumption

- Eliminates biofilms. Reduces scale and corrosion. Improves heat transfer.

- Keeps water in an oxidized state and reduces blow down

- Lowers electric costs

- (LEED Credits) Energy Star building program contributor

- 24/7 Remote IoT Management provides analytics and live read of operations and savings

- Mitigates COVID by improving ventilation

- Reduces maintenance cost and increases equipment life cycle

Free Analysis to Illustrate 25-40% Return on Investment

- Legacy data centers can achieve an immediate cost savings

- There is no other comprehensive non-chemical tech with monitoring and UV

- Pangea’s president is SME in water treatment, filtration and O3

Green friendly wet cooling solutions

Flozone Services takes a full service approach to understanding and managing the wet-side of our customers HVAC heating and cooling systems. The Flozone Integrated Water and Energy Management Program is designed as a “wellness” program for HVAC cooling water. Where most water treatment programs are designed to “diagnose and dose chemicals” periodically to control biological activity and scale, often monthly or bi-monthly; our program is designed to maintain consistent water quality 24/7 through the combined use of advanced proprietary technology and water chemistry.

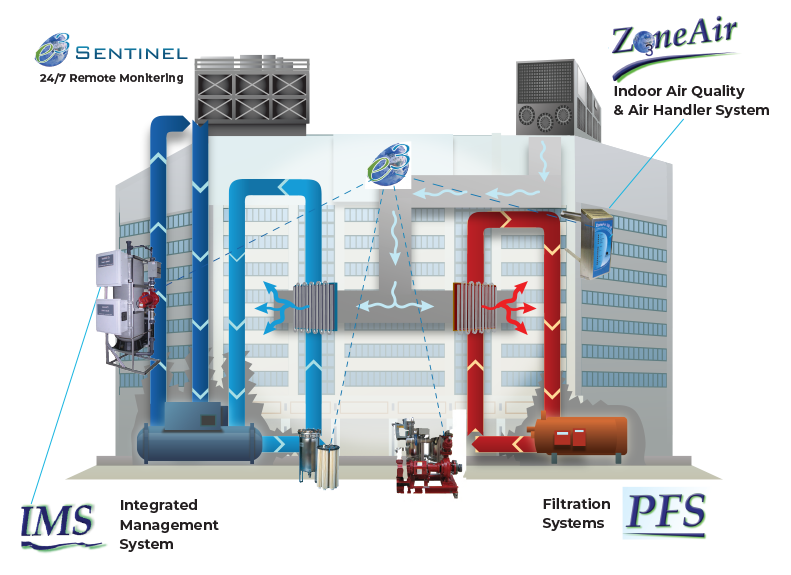

Flozone Services relies on a combination of E3 Sentinel 24/7 remote monitoring and controls, a patented Quantum ElectroDynamics (QED) technology and ozone to eliminate chemical usage. The IMS utilizes a side stream application and is typically set to cycle the system water through the contact tank several times daily. Flozone IMS units are custom designed for each customer, with the “QED”, ozone generators, mixing columns, and distribution systems designed and sized or the particular application.

Cooling Towers and Evaporative Condensers naturally scrub particles from the air, accumulating airborne dirt and debris in the sump. Accumulation of airborne debris cannot be prevented with a water management system. Scaling is a hard crusty mineral accumulation throughout the wetted areas of the cooling tower fill, chiller tubes and or plate and frame heat exchangers and is easy to differentiate from accumulated dirt and debris. We recommend that the system be cleaned of accumulated airborne debris on a routine basis.

Flozone guarantees clean cooling tower fill and chiller tubes (Heat Exchange Surfaces) under normal operating conditions. It is expected that the application of Flozone’s Integrated Water & Energy Management System will result in consistently clean heat transfer surfaces. However, in the event cleaning of any chiller tubes, heat exchanger or tower fill is required due to scale or bio-film accumulation caused by an ineffective water treatment program, Flozone will be responsible for the cleaning at no cost to the Customer (Splash drain covers may reflect some “green” &/or scale due to surfaces being outside the normal water flow). A Flozone representative is required to be present for any cooling tower, chiller or heat exchanger inspection to assist in determining the cause of any scale or bio-film accumulation.